The pulse mold waterway cleaning machine uses the pulse water molecule blasting technology to form water molecule blasting in the mold waterway. The scale and rust sludge will be blasted into blocks or granules, and then be dissolved it into powder with special cleaning agent and thus be cleaned from the mold waterway without secondary blockage.

TEL

+86-13303815638| Product Name | Model | Quantity |

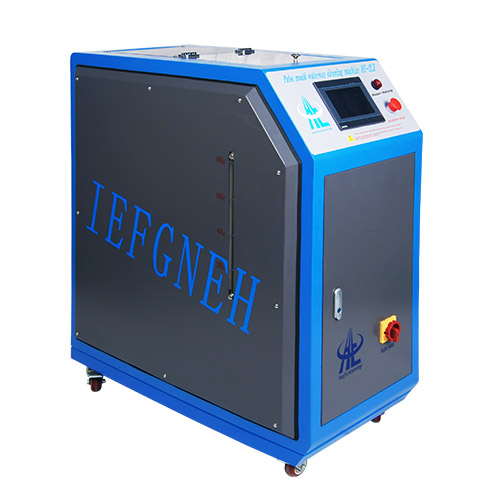

| Pulse mold waterway cleaning machine | HF-2LZ | 1 |

| The project content | requirements |

| Touch screen | Zhongda Youkong |

| Program controller PLC | Zhongda Youkong |

| The water pump | Grundfos |

| Pulsed solenoid valve | Germany |

| Stainless steel multistage water pump | ≥ 3kw protection class IP54 |

| The pump pressure | 7KG |

| Pulse pressure | 8KG |

| Whole machine size | L1130*W560*H1230(mm) |

| The tank volume | 80L(Plastic water tank) |

| Total electrical capacity | ≥4KW |

| Operating temperature range | 5-60℃ |

| Power Supply | 380v/50HZ(3P+E) |

| Number of inlet and outlet pipes and diameter of inlet and outlet pipes | (16 4fen, 2 1cun)(Note:1fen is about 0.33333333cm, 1cun is about 3.33333333cm). |

| Intake pressure | 6-8kgf/cm2 |

| Intake pipe diameter | 10mm |

| Pipe | Stainless steel 304 seamless tube |

| Nylon heavy-duty casters | 4 actuating wheels, lock function. |

| The project content | Configuration |

| The automatic control | PLC+ touch screen control, one-click start |

| Pulse cleaning | Pulse cleaning, three gears: fast, medium and slow |

| Blow dry function | Automatic blow dry |

| Positive and negative cleaning | Free switch of three pulse gears, positive and negative cleaning |

| Pressure detection | Real-time pressure display, real-time detection |

| Flow detection | Independent flow detection, flow memory |

| Protection device | Overload pump alarm if the water level is too low, the system pressure is too high |

| Incase line | Inside the cabinet, the wiring blocks and terminals are installed with insulation protection against electric shock. The wiring blocks are installed with insulated terminal cover (PC material), and the terminals are covered with insulation number pipes. |

| The power supply is directly connected to the leakage protection device | Installed with leakage protection switch |

| Safety device | Install overload and short circuit protection circuit breakers and safety fuses etc. |

| Number | Name of spare parts | Type specification quantity | Note |

| 1 | Cleaning machine | / | 1set |

| 2 | Fast interface | Φ8mm-Φ14mm | Quick connection between mold and machine |

| 3 | Cleaning agents | 1bag | 2kg/bag |

| 4 | The wiring diagram | 1 | English description |

| 5 | The instructions | 1 | English descriptio |

| 6 | 3D operational video | Viewing on public account |

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.